7 Common Repairs To Extend a Shipping Container’s Lifespan

Written by Susan Nalevac | August 19, 2022

A shipping container is made of an extremely durable construction, but even containers succumb to wear and tear after many years in service. In our guide, we’ll explain how long shipping containers last, their most common issues, and what simple repairs and maintenance can extend their lifespan.

In This Article:

How Long Do Shipping Containers Last?

How long can one expect a shipping container to last? That largely depends on its purpose. Shipping containers are built to last for a long time, especially if well-maintained.

A shipping container used exclusively for transit—taking it thousands of miles worldwide over oceans, roads, and train tracks—typically stays in steamship line inventory for an average of 14 to 18 years.

Once it moves from the steamship lines to the wholesalers for commercial sale, the containers are graded based on strict criteria and sold according to grade. Click on this link for more about the individual container grades: Shipping and Storage Container Grades.

A well-maintained and protected container used for other purposes such as storage can last well beyond 35 years.

Pro Tip: If you want to buy a container for aesthetic appeal, consider a “one-trip” container that’s only been used once.

Most Common Types of Shipping Container Damage & Problems

What type of damage should an owner of a storage container expect? Over its lifespan, some of the most typical problems a container will face are rust, broken doors, and a moldy interior.

Rust

When you buy a steel storage container, the first maintenance priority is ensuring that rust is not allowed to gain a foothold. Naturally, salt and water could wreak havoc on a steel box that spends a lot of time at sea or outside in the elements.

When choosing a new container, ensure it doesn’t contain rust and always check for any buildup inside and outside the container. Minimal surface rust is acceptable when choosing a used container.

Broken Doors

If a container sustains damage or falls into disrepair, the doors are typically the first to go. A container’s doors get used the most. If the structure becomes dented or rusted, the doors can become unmovable and the entire container unusable without a total replacement.

Moldy Interior

Rust is a container’s nemesis, but any moisture buildup is a bad sign that owners must catch before it becomes a significant problem. If you smell a faint, moldy scent in your interior, you want to take care of it immediately.

Clean and remove the mold and look for where the moisture came from inside the container.

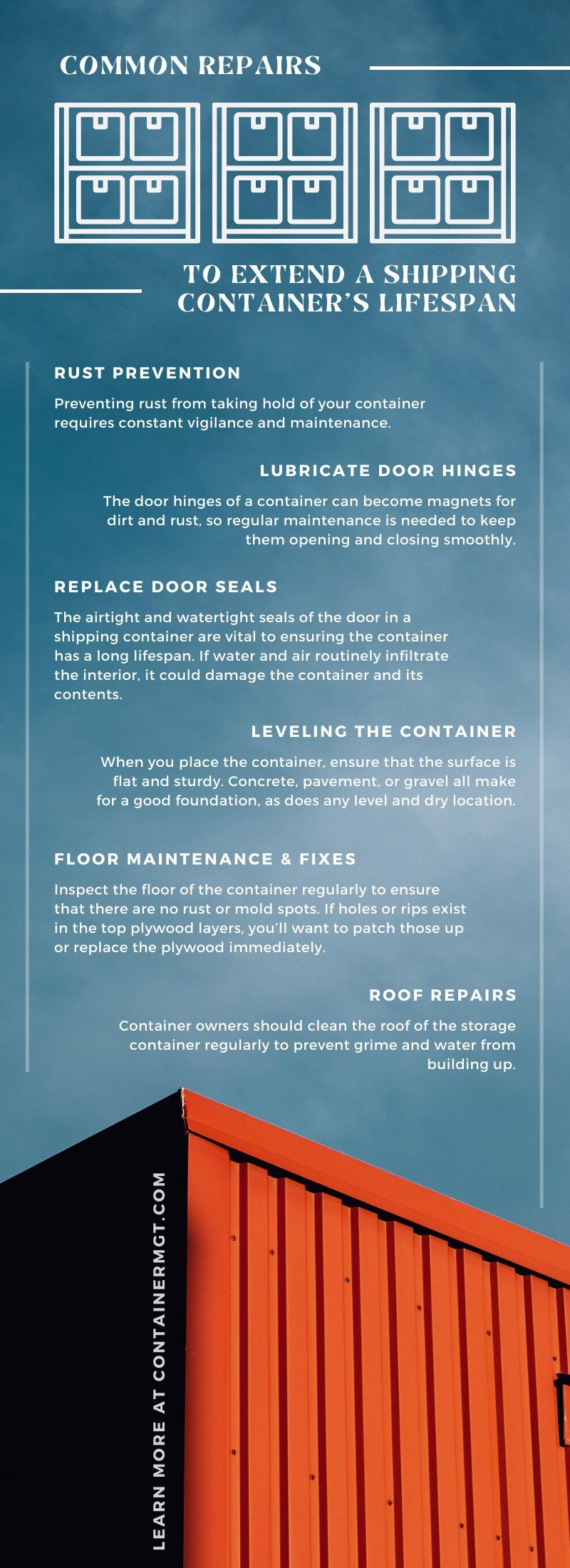

Repairs & Maintenance That Extend a Container's Lifespan

How can an owner prevent their container from eroding? We can help with that too, thanks to our list of common repairs that will help extend the lifespan of a shipping container.

Rust Prevention

The first and most important thing you want to be on the lookout for with your steel container is rust. Preventing rust from taking hold of your container requires constant vigilance and maintenance.

First, it means cleaning the inside and outside of the container and ensuring that there are no potential entry points for water and moisture to get inside. The roof is an especially vulnerable part of the structure where water can pool, so clean off and dry the top as often as possible.

Pro Tip: Dents are potential rust points and should be repaired immediately before rust can corrode the exterior.

Lubricate Door Hinges

Perhaps the most typical problem for a shipping container is the doors working incorrectly. The door hinges of a container can become magnets for dirt and rust, so regular maintenance is needed to keep them opening and closing smoothly.

Lubricate the door hinges of the container regularly and keep them clean to prevent dirt and grime buildup. If they’re stuck or bent, it could be from an uneven weight distribution. You’ll need to adjust the weight balance in the container or even use a jack to even it out.

Replace Door Seals

The airtight and watertight seals of the door in a shipping container are vital to ensuring the container has a long lifespan. If water and air routinely infiltrate the interior, it could damage the container and its contents.

If you notice pools of water inside the container, it could be from faulty rubber door seals. Rather than replacing the container’s doors or the container entirely, replace the rubber seals and see if that fixes the leaking problem.

Leveling the Container

A shipping container must be placed on an even and flat surface. A container distributes its weight through its four corners. If those corners are not even with one another, the weight is distributed unevenly, and the frame can become bent or damaged.

When you place the container, ensure that the surface is flat and sturdy. Concrete, pavement, or gravel all make for a good foundation, as does any level and dry location.

Floor Maintenance & Fixes

A container on uneven ground or with water pooling underneath could show problems with its floor. A container’s floor has two parts: steel-cross lower support and waterproof plywood above.

Inspect the floor of the container regularly to ensure that there are no rust or mold spots. If holes or rips exist in the top plywood layers, you’ll want to patch those up or replace the plywood immediately.

Roof Repairs

The roof is the most vulnerable part of a shipping container as it bears the brunt of rain, wind, and sun. While a container roof is waterproofed and sealed, it can still succumb to the elements without adequate repairs and maintenance.

Container owners should clean the roof of the storage container regularly to prevent grime and water from building up. Any possible dents or holes should be fixed and patched up to avoid water and moisture from getting inside the container.

Fresh Coat of Paint

If you’ve had a shipping container for years and it’s had the same coat of paint, it probably could use a fresh coat. Paint doesn’t just make the container look nice but adds an extra layer of protection to the exterior against rain, wind, and sun.

After years of brutal punishment from the outdoors, a container’s paint could peel, fade, or chip, leaving an opening for rust to penetrate and infect the container. When the container’s exterior paint shows signs of fading or chipping, get it repainted immediately to preserve its outer protection.